Blade Tracking and Pitch Curve

Up to this point all of the setup was done without the motor

connected, and using the Idle Up Pitch curve. Now it is time to set

the blade tracking, but before we do that we need to setup the Normal

pitch curve. Select the Normal Pitch curve button, and we are going

to set the curve for a simple linear baseline for testing the blade

tracking. We want a curve that will give us enough blade and damper

flex at mid to slightly higher than mid throttle. This is typically

the hover stick location, and that means the blades are lifting the

full weight of the model. This is where we want to observe the blade

pitch.

Note: Experienced pilots can manage tracking errors in flight, and

will typically check their blade tracking in the air rather than

mounting the model to a test stand or weighting the model to the

ground. Checking it in the air is by far much safer than on a stand

or on the ground because blades can and will come off. When they do,

people and property can be damaged.

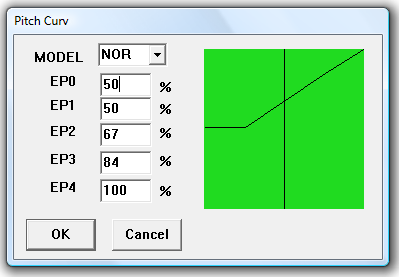

Setup the Normal settings as illustrated below (Fig 14).

Fig

14

Warnings: The following

procedure requires the motor to be running. This is a dangerous

process. Take all precautions so that you do not incur injury to

yourself or others, or property. You will need to secure the

helicopter to an immovable object. I use a home made test stand made

of common parts such as 1 1/2” irrigation (PVC) pipe with a

plexiglass platform mounted with a light weight gimbel (Fig. 15).

Some users tape the landing gear to the floor, and lay a heavy

tool through the landing skids. Whatever method you use, be sure the

helicopter will not come loose. Some people perform this test in

flight. If you do not feel comfortable with performing this test with

the helicopter mounted to an immovable object, then perform the

adjustments between test flights.

Do not rely solely on the four tiny skid mounting screws to hold

your model to the ground. Place a strap through the frame under the

main gear as a precaution.

Do not trust brand new blades or blades that were used during a

crash. They may appear perfectly healthy, but tiny fractures can

instantly become a full blown disaster. When testing blades, always

stay at a safe distance the first time you engage the throttle. We

are speaking here from experience.

Fig

15

Warning: Blades are held on by

small screws or nuts. They have been known to come off at high RPM.

The first time (and actually anytime) you startup the helicopter

motor, be at a safe distance to minimize injury or damage. Where

safety goggles as you will be looking down the business end of the

blades as they rotate at a very high speed.

Power everything off. Make sure the radio's Idle Up switch (SW-B)

is set to OFF (away from you).

Set the Throttle Cut switch (SW-A) to ON (towards you). Connect

the motor wires to the ESC. Mount the helicopter to a test stand or

some immovable object (see warnings above). The objective of this

test is to adjust the blades so that each blade passes through the

same location at the same place. As the blades rotate and apply lift,

they will flex as they take on the weight of the model. The blades

must follow each other to evenly push the air. If one blade is

tracking higher than the other, it is robbing the lower blade of its

lifting capability. This results in reduced overall lift, unstable

flight, and vibration.

Set the radio left trim slide for throttle (vertical trim on the

left stick) to the bottom position. All other trims in their centered

position. Set the throttle stick to its lowest position.

Turn on the radio transmitter first. Attach the battery power

connector to the ESC connector on the helicopter. Move to a safe

distance from the helicopter. Switch the Throttle-Cut (SW-A) switch

away from you to the OFF position. Slowly power up the motor. Bring

the motor up to slightly more than mid stick. The blades should start

applying pitch and will lift in the blade grips.

Increase the throttle to about ¾ throttle and observe the

leading edge of the blades. You will notice the blades begin to flex

upwards as they take on the weight. This test must be done with the

blades producing thrust (lift) so that end play is removed from the

blade grips and feathering shaft and the dampers have the full weight

of the model.

Determine which blade is traveling higher than the other by

looking at the leading edge of the blades. The main blades travel in

a clock-wise direction looking from above the helicopter. If you are

facing the nose of the helicopter, the blades leading edge will be

coming towards you to your right (the helicopter's left side). The

reference blade we used earlier had the red decal. You want to

determine which way to move the non-referenced blade to get it

tracking with the reference blade.

Fig

16

In the illustration above (Fig. 16), the lower blade is marked

with three black lines that are visible as the blades rotate at high

speed. This is observed by looking at the leading edge of the blades.

If the black marks in Fig. 16 were on our reference blade, then we

will want to adjust the opposite blade to have less pitch (leading

edge needs to be lowered). Keep in mind that our referenced blade was

used for setting our pitch, so we want to bring the other blade into

the same tracking as our referenced blade. Since the opposite blade

is tracking higher, we will need to reduce it pitch. This is done by

removing the blade grip link off of the blade grip ball, then

lengthening that link to force the leading edge downwards. Increasing

the length of this link will bring the leading edge of that blade

lower.

Rod ends are built to access the ball from only one direction. The

manufacturer will provide a mark such as a ring around the larger

hole. When adjusting the rod length, make complete turns so that the

correct hole of the rod end is facing the ball. Only adjust one turn

at a time, and retest the blade tracking.

Note: In some of the forums, remarks have been made that the small

links at the blade grips (Fig 13) are for fine adjustment, and the

long links to the swashplate are the rough adjustment. This is not

the case. The SF mixing arm is a fulcrum with the short end connected

to the blade grip with a link. With the long end of the SF mixing arm

is connected to the swashplate with the long link. The way a fulcrum

works is it takes more movement of the long end to produce a small

movement on the short end. Therefore the long end produces less

change per turn of its linkage. Less change means finer adjustment.

Adjust the proper linkage so that at ¾ throttle the blade

tips line up as they spin around.

At this point you should now have the blade tracking set so

that you only see one blade as it rotates around with enough throttle

speed to lift the helicopters weightAdjust the proper linkage so that at ¾ throttle the blade tips line up as they

spin around.

At this point you should now have the blade tracking set so that you only see

one blade as it rotates around with enough throttle speed to lift the

helicopters weight.

Prev

Next - Tail and Gyro setup